Standard and Customised Thermal Shock Chambers

JB Environmental Engineering Ltd supply a range of standard Thermal Shock Test Chambers and customised Thermal Shock Test Chambers for the shock testing of electronic components & Assemblies for the electronics, automotive, defence and aerospace industries. A Thermal shock chamber testing is applied to products to observe their features and failures induced by multiple materials and their thermal expansion coefficients. The thermal shock test chamber involves moving the test item between alternating high and low temperatures in a very short time (≤15 minutes), this causes thermal shock stresses to be introduced in the test item to test the items resilience to rapid temperature changes.

Thermal Shock Test Chamber testing simulates the significant temperature variations that a product may see in real-world use by users. Consider the shock a smartphone battery gets when someone goes from chilly winter weather outside to the comfort of their own house. For example, imagine leaving an airport runway in 45°C weather and then reaching peak altitude in -30°C to -56°C temperatures. The thermal shock test chamber has two zones: one for heat and another for cold, with an optional third zone for ambient temperature as a backup.

Thermal Shock Test Chambers – Various Options

Our thermal shock test chambers are supplied in a variety of sizes to enable the use to test many sizes of test samples and are used to test component and board electronic assemblies for environmental stress. Our innovative thermal shock test chamber design transports the product between two temperature-controlled chambers, passing equal quantities of conditioned air over the product and resulting in quick temperature changes thereby expanding and contracting key elements. Induced heat stresses can uncover latent manufacturing faults in electronic sub-assemblies and other components.

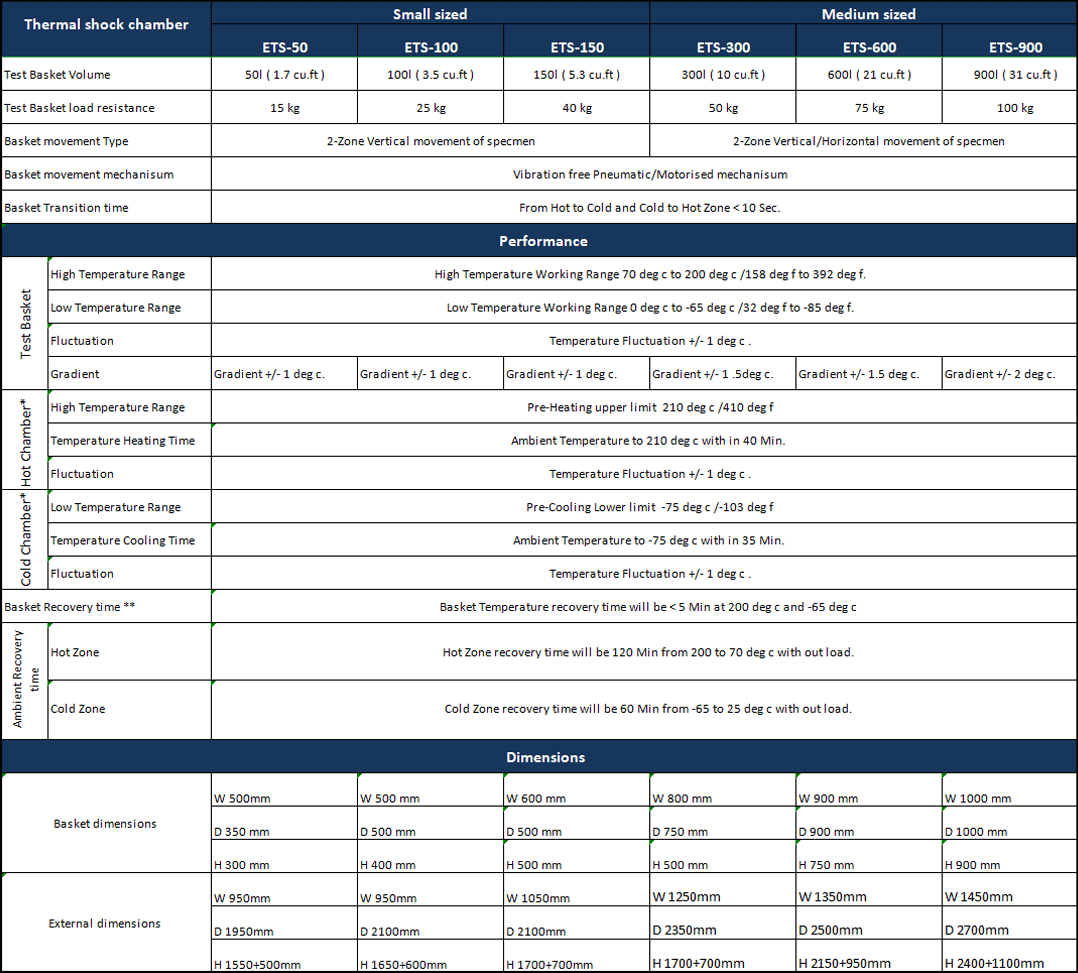

The Thermal shock test chamber consists of a product carrier basket inside the chamber that transfers the product under test between two temperature zones, one hot and the other cold that are independently controlled. Users may easily monitor the product as it is transported between the different temperature zones thanks to built-in viewing windows. The Thermal Shock Test Chamber are available in different volumes to suit the varied testing needs, and also in Vertical or Horizontal models consisting of cold and hot zones with product carrier baskets of sizes 50, 100, 150, 300, 600, and 900 litres which transfer the specimen under test between the cold and hot zones using electro-pneumatic / motorized basket movement.

Typical Features of Thermal Shock Test Chambers

For full details and requirements, please Contact Us.

Learn More & Contact Us

Interested in our Thermal Shock Test Chambers?

Have any questions or need further information? Feel free to reach out.

Our knowledgeable team is ready to assist you with any enquiries you may have.

After sale service is an integral part of our business: Our services include complete technical and engineering support to our customers round the clock, repair, maintenance, refurbishments, spare parts etc.